Faster Fault Alerts | Fresher Milk | Smarter Dairy Operations

2025 Impact Awards Winner Case

“Working with Scopious IoT and Milesight has given us a reliable, easy-to-manage monitoring solution that fits the way farmers actually work. The visibility and efficiency gains have been immediate, and the system has proven both scalable and robust in everyday use.” Hayden Walsh - General Manager - Agora

Background

The dairy industry in New Zealand demands precision and reliability to maintain milk quality throughout every stage of production.

Agora, a sister company of Deosan with more than 20 years of industry experience, recognised the need for on-farm technology that was costeffective, transparent, resilient, and simple to use.

To meet this need, Scopious IoT developed a smart milk vat monitoring system that integrates Milesight LoRaWAN® sensors and gateways with the Scopious IoT platform. The solution provides continuous, near real-time visibility of vat operations, helping farmers reduce losses, ensure compliance, and protect milk quality.

Challenge

Lack of Real-Time Visibility

Traditional monitoring methods offered limited insight into vat temperature, fill levels, and agitator performance, making it difficult to detect issues before they affected milk quality.High Operational Burden

Manual checks and maintenance were time-consuming and prone to error, taking valuable time away from other essential on-farm tasks.Need for an Easy & Scalable System

Farmers required a simple, plug-and-play system that could be deployed quickly, scaled easily, and managed remotely without technical complexity.

Solution Approach

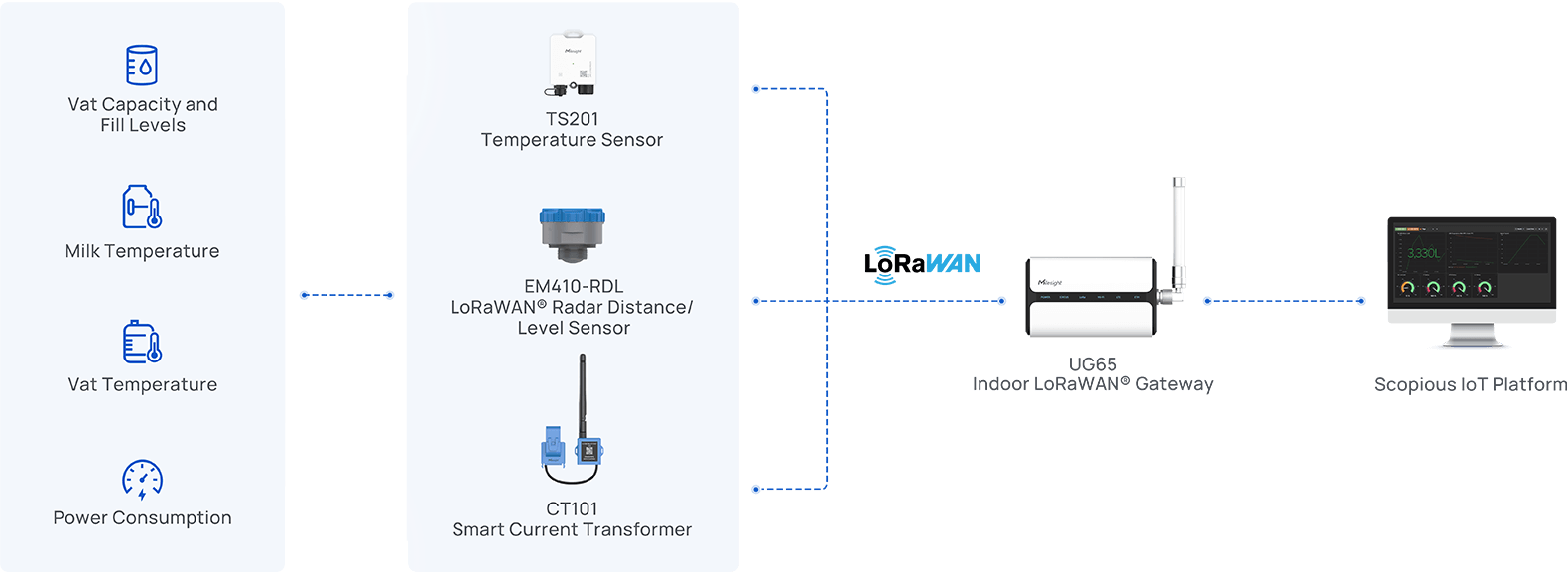

EM410-RDL Radar Distance/Level Sensors are mounted on top of milk vats to measure capacity and fill levels in real time. These work together with temperature sensors and CT clamps.

CT101 Smart Current Transformers are used to monitor vat agitators, ensuring consistent milk mixing and stable temperature distribution.

TS201 Temperature Sensors track the temperature of the milk going into the vat as well as the vat’s internal temperature.

Through its sister company, Go Wireless NZ, Scopious IoT leveraged an

established partnership with Milesight to develop a smart milk vat monitoring

system that combines reliable LoRaWAN® hardware with intelligent data

analytics.

All sensor data is transmitted via LoRaWAN® to the Milesight UG65 Semi-

Industrial Gateway, providing long-range, stable communication across the farm. The gateway securely forwards data to the Scopious IoT Platform, where it’s visualised through an intuitive dashboard.

Within the platform, smart alarms notify users of key events such as agitator faults, vat level changes, emptying cycles, hot wash completion, and temperature peaks. This integrated system provides farmers with real-time visibility into the entire milk handling process, supporting faster fault resolution, reduced downtime, and more consistent milk quality management.

Results

The combined expertise of Milesight, Scopious IoT, and Agora has produced a scalable, reliable milk vat monitoring solution that is transforming dairy operations across New Zealand. This solution not only simplifies daily operations for farmers but also sets a new benchmark for smart dairy management in the region.

Ease of Deployment

The system is easy to install, requires minimal training, and can be scaled to multiple vats or sites with little configuration effort.

Faster Fault Detection & Reduced Downtime

Near real-time alerts allow farmers to quickly identify and fix issues such as agitator faults or abnormal temperature changes, reducing spoilage and equipment downtime.

Improved Milk Quality & Safety

Continuous monitoring ensures optimal temperature control, maintaining freshness and meeting dairy quality standards.

Cost-Effective & Scalable Operations

By leveraging LoRaWAN® connectivity and centralised dashboards, farmers gain dependable monitoring at a fraction of the cost of wired systems, with flexibility for future expansion.

Products:

• EM410-RDL LoRaWAN® Radar Distance/Level Sensor

• TS201 Cost-Effective Temperature Sensor

• CT101 Smart Current Transformer

• UG65 Semi-Industrial LoRaWAN® Gateway

Next Steps:

Building on the success of the smart milk vat monitoring solution, Scopious IoT plans to continue expanding its capabilities and reach:

System Expansion and Integration:

Extend monitoring across more farms and integrate with existing farm management systems for richer insights.

Advanced Analytics & Predictive Maintenance:

Enhance the platform with AI-driven analytics to predict equipment failures, optimise vat operations, and further reduce operational costs.

Cross-Sector Applications:

Adapt the solution to other agricultural and industrial processes, leveraging the same LoRaWAN® infrastructure for water, energy, and environmental monitoring.

Conclusion:

The collaboration between Scopious IoT, Milesight, and Agora highlights the value of connected technology in transforming traditional farming practices. By combining reliable hardware with intelligent data insights, this smart milk vat monitoring system empowers farmers to protect quality, reduce costs, and make data-driven decisions with confidence.

As Scopious IoT continues to expand its solutions across sectors, the company is driven by collaboration, connecting reliable hardware, innovative ideas, and local expertise to deliver smarter, more sustainable operations powered by actionable environmental data.

Why choose Milesight:

Scopious IoT, through its sister company Go Wireless NZ, has partnered with Milesight since 2019, drawing on their innovation, flexibility, and strong technical collaboration.

For this project, Milesight provided extensive hardware customisation, from device branding and packaging to fine-tuned product integration, ensuring the solution aligned with Agora’s professional, plug-and-play expectations.

As Scopious IoT puts it:

“We couldn’t have done it without Milesight. Their support, flexibility, and dedication have been instrumental in turning our concept into

a fully realised solution.”

This collaboration demonstrates how the combination of innovative hardware, technical expertise, and shared ideas can turn complex challenges into practical, scalable solutions for the dairy industry.

Smart farms start with smart partnerships.

What started as a joint vision between Scopious and Agora NZ Limited, to make dairy smarter through IoT, has just been recognised on a global stage earning the IoT Award at the Milesight IoT 2025 Impact Awards! Watch as Josh shares the story behind the project and a heartfelt acceptance speech that captures why collaboration drives real progress. ▶️ https://www.youtube.com/live/sIFrvPmhCiM?t=1089s

Book a 1 Hour FREE Consulting Service

Leave your number and we will get in touch, your first hour is free!